I started out with very little knowledge in boat restoration. What I had was experience in woodworking, painting, plumbing, and electrical from my work in construction. I had also built 4 small wooden boats; three 16 foot McKenzie River drift boats and one Doug Hylan designed 13 foot Maine Peapod. I used three main books for reference during this project, Don Casey's This Old Boat, Nigel Calder's Boatowner's Mechanical and Electrical Manual, and Beth Leonard's The Voyager's Handbook. I also talked to boat owners and read blogs on the internet and of course Googled.

The 1974 Hallberg Rassy Rasmus 35 Hull number 337 was in serious disrepair. It was a wreck. It took me 5 years(2.5 years part time and 2.5 years near full time) to turn it from a wreck to near new condition. The work is documented here: www.lizardheadone.com. Everything on this boat was replaced except for mast and boom, a few cleats, and the interior cabinetry(I did replace the galley cabinetry). I did 99.999% of the work myself. It took thousands of hours in labor, tens of thousands of dollars, and energy and motivation that at times became hard to come by. This project became a grueling marathon that never ended. But it did.

The transformation started almost immediately after stepping the mast. My body released the tension and anxiety that had built up over the last two years of restoration. My legs went weak. It was actually hard to stand for a few hours. A sense of calm and satisfaction was replacing anxiety and stress. The boat restoration had taken it's toll on me. The burden of a job of this magnitude was lifted and it felt good. Now it's time for ME to rehab.

In hindsight, I would have taken another coarse in becoming a boat owner. I would have purchased a boat in better condition for starters. One with a nice equipment list. One that would take far less effort to bring back to condition. There was no financial advantage to buying a low cost boat and rebuilding it. With all the advantages that I had (boat shed at my house, woodworking shop, time, and sufficient funds) the project was almost too much for me. I had doubts many times about finishing. Posting my work on the internet really helped in keeping me motivated. I heard from folks around the world and they gave me encouragement and advice. Thank you.

This restoration project did, however, give me a enormous sense of accomplishment. It also gave me knowledge necessary to repair any system on the boat. I really know this boat. This project was a journey in itself, and even though I doubt I would ever attempt something like this again, I believe I will always be glad that I did it. ONCE.

Cheers

Pat

Talk all things Hallberg Rassy Rasmus, Hallberg Rassy's first production sailboat.

Hallberg Rassy Rasmus 35

An Old Classic

Sunday, December 9, 2012

Saturday, December 8, 2012

Mast is stepped

I hired a boom truck to step my mast a couple days ago. Everything went very smooth, even though I have never stepped a mast this large. The crane operator was good. He used nylon webbing only and started just above the winches around four cleats and put a half hitch there, then went up just above the spreaders and put another half hitch and one more half hitch about 6 feet from the top. No damage to even my windex. Pics below.

Sunday, December 2, 2012

Mast Step Orientation on Hallberg Rassy Rasmus

I asked a question about mast foot orientation and received some answers and some more questions. I have learned from initial replies that the connection of the mast to mast foot on the HR Rasmus varies between hull numbers.

First let me clarify some terms(from Selden Mast):

Mast Step is the hardware bolted on the boat to accept the mast.

Mast Heel is the fitting on the base of the mast that fits on the mast step.

From the information provided me I can say that on all boats the mast is connected to the mast foot by one bolt which bolts through a hole in the mast step and a corresponding hole in the mast heel. My guess is that they don't use two bolts in this configuration because it would stress the bolts as the mast pendulums. Some boats have this bolt in the center of the mast step and other boats have it on one side of the mast step. My boat has the bolt on the aft end of the mast step but other boats have the bolt on the forward end of the mast step. On the opposite end of where the bolt is located, there is another bolt, BUT this bolt fits in a slot in the mast step so the mast can pendulum without stressing the bolt. This bolt help keeps the mast in its place in the for and aft orientation. Below is drawing.

Since boats have all three of these configurations on attaching mast to deck, I would guess all work just fine.Thanks everyone for the help on this. I appreciate it.

Pat

First let me clarify some terms(from Selden Mast):

Mast Step is the hardware bolted on the boat to accept the mast.

Mast Heel is the fitting on the base of the mast that fits on the mast step.

From the information provided me I can say that on all boats the mast is connected to the mast foot by one bolt which bolts through a hole in the mast step and a corresponding hole in the mast heel. My guess is that they don't use two bolts in this configuration because it would stress the bolts as the mast pendulums. Some boats have this bolt in the center of the mast step and other boats have it on one side of the mast step. My boat has the bolt on the aft end of the mast step but other boats have the bolt on the forward end of the mast step. On the opposite end of where the bolt is located, there is another bolt, BUT this bolt fits in a slot in the mast step so the mast can pendulum without stressing the bolt. This bolt help keeps the mast in its place in the for and aft orientation. Below is drawing.

Pat

Thursday, November 29, 2012

She's back in the water

Saturday, November 24, 2012

Please Help on Mast Step Orientation

Wednesday, November 21, 2012

Marine Survey and Insurance

I was able to find a marine surveyor here in Little Rock and he was unusually busy at this time of year but was able to squeeze me into his schedule. Insurance companies require a survey before they will offer their coverage. I was dealing with BoatUS Insurance company. Before the survey they were only going to give me coverage up to $25,000. After they accepted the survey, they upped their coverage to $50,000. That will cover about half of what I have in the boat if it's totaled but I knew going into this project that this wasn't going to be a money making venture and I would certainly lose money. I will carry coverage insurance for at least a year to gain experience and will later adjust it as I see fit. I am scheduled to move the boat the week of Nov. 27th. I only have a 10 mile move from my house to Little Rock Yacht Club. I am cutting it a bit close, but still plan to leave in the middle of January for my trip to the Bahamas. It's getting very exciting indeed.

Saturday, October 27, 2012

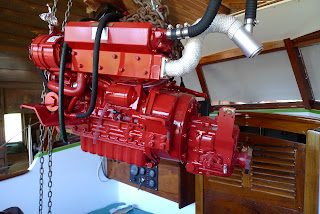

Beta Engine Installation Photos

Below are photos of my Beta 38 engine installation. Thanks to everyone for posting information to help me through this.

|

| Beta 38 |

|

| The high rise exhaust elbow and hose exiting straight back from engine. |

|

| I added a shelf above the shaft just under the aft cabin closet floor to hold the Vetus LSS50 water lock muffler. |

|

| Exhaust hose runs straight back under the aft cabin floor. |

|

| And continues under the aft cabin settee. |

|

| To the Vetus LT Gooseneck at the transom. |

Friday, October 26, 2012

Engine Problem Solved

I finally found the cause of the dying engine. I had an air leak on the fuel lift tube where the nylon tube connects to the aluminum fitting that screws onto the tank. It was a newly replaced part. It's crazy all the sub standard equipment being made. I found it by unhooking the fuel line from the fuel tank (the other end goes into the Facet lift pump) and sticking that end in fresh clean fuel in a bucket and unhooked the fuel line going into the Racor fuel filter and sticking that in the same bucket of fuel (isolating the fuel pump). I turned on my Facet fuel pump and watched for bubbles going up in the bucket of fuel. No bubbles. So then I re attached the fuel hose to the fuel tank and turned on the Facet pump again isolating the tank fitting. I got bubbles coming up in the bucket of fuel. So, the leak has to be at the tank fitting because all of the fuel lines down stream of the Facet pump are pressurized meaning if I have a leak downstream of the Facet pump it will show up as fuel in the bilge, not air in the lines. I changed out the fuel lift tube assembly and the engine ran beautifully. Boy has this little air leaked been frustrating. This is my first engine installation and I knew I would make some mistakes. Thankfully none of them have been catastrophic. They have been very frustrating but I am learning a lot fast and that, in itself, will be worth it in the long haul.

Cheers

Pat

Cheers

Pat

Wednesday, October 24, 2012

Help! Beta Marine Engine Keeps Dying

Ok, I have redone my exhaust system much like Dave's and Martin's systems. I put the Vetus LSS 50 water lock muffler under the aft cabin closet on a shelf I made just above the prop shaft. That gives me the required drop from the water injection point to the muffler. Then ran the pipe straight back to the gooseneck mounted at the transom. I left the anti siphon loop on the water injection hose high in the starboard locker. That meets the Vetus's installation requirements. So it seems to work fine sitting here in my yard. We shall see when I get into some waves. But, THE BETA ENGINE STILL DIES ON ME!!!!!! It is still getting air in the line somewhere. Its not the fuel level, I checked that. I have at least half a tank of fuel. My Racor fuel filler lid was not screwed on really tight, so I tightened that down really snug. That seemed to help and I thought I had it fixed but after running it for several minutes, shutting it off, then restarting and running for just a few seconds, BAM, the engine dies again. This is driving me CRAZY!!! Any suggestions as to what the problem could be would be greatly appreciated. I will get some pictures posted in a few days of the entire install.

Cheers

Cheers

Monday, October 22, 2012

Thought I would chime in here Pat with my exhaust input. Above is the configuration of my exhaust. Originally had the vertical Vetus rubber muffler and 2 up/down galvanized piping. The inside had corroded and piled up in the muffler promoting back flow of water. I found that problem while rebuilding the engine and finding seized rings on #4 piston. Now I have a Vernalift in the aft cabin locker. Holds about 3 gallons and the long "new" exhaust run probably holds an other 2 gallons.

I have a Electric Walbro diesel lift pump to prime the system prior to starting. It does not stay on. I have it on a push button while I push the other button for the heaters. Now with the rebuilt engine (Westerbeke W46), it rarely cranks more than 2 seconds and fires.

I have a Electric Walbro diesel lift pump to prime the system prior to starting. It does not stay on. I have it on a push button while I push the other button for the heaters. Now with the rebuilt engine (Westerbeke W46), it rarely cranks more than 2 seconds and fires.

Tuesday, October 16, 2012

Engine Exhaust Problem Located

After getting water in the engine from a back flow of wet exhaust, I found the problem. My exhaust muffler inlet is two inches higher than the high rise exhaust elbow fitting on the engine. I made a big mistake. I relied upon a previous installation as being correct. Since my exhaust elbow is in the starboard locker out of sight from the engine room, it wasn't so easy to spot. That's my excuse anyway! So, as long as the engine starts quickly you don't see a problem. But as soon as a hard starting situation appears, the hose between the exhaust elbow and muffler quickly fills up with water, as the engine doesn't produce the exhaust pressure necessary to push the wet exhaust water up and over to the muffler. The problem is I don't have the space to lower the muffler or enough space to raise the elbow to get the recommended 9 inches of drop from the exhaust elbow to the muffler. Hmmm. I can custom make an extension to my exhaust elbow to raise it above the muffler at a maximum height of maybe 4 inches above the muffler inlet. That puts the top of the exhaust elbow at the very top of my engine room ceiling. But it still doesn't meet the recommended 9 inch drop. What to do. Any suggestions are welcome.

Pat

Monday, October 15, 2012

Revision to my last post

Well I have figured out some things with the engine install. And some lesson are learned the hard way. It has been hard to start of late(last two days) and I have been having to re bleed the fuel lines. I thought is was the added Facet fuel pump that blew a fuse that caused the hard starting problems. Nope. I found out what was causing the hard start. I didn't put enough diesel in the tank and it was sucking air. I also found out what can happen when you crank the engine several times without it starting. I got water in the engine!! Today I checked the oil level prior to starting and saw a milky coating on my oil dip stick. I called Beta and they gave me a plan to flush the engine of the bad oil. I pumped out the oil, replaced the bad oil with good, replaced the oil filter, and ran the engine for a couple of minutes. Then repeated the above steps four times. Ended up running 16 quarts of good oil thru it and using up 4 oil filters and it looked like it cleaned up well. I will probably do it a few more times tomorrow just for good measure. It is running great now that have the fuel tank filled up to an appropriate level and have nice clean oil in the engine. And luckily it was fresh water, so no salt problems should occur. Having hopefully dodged a bullet, I now have to figure out what went wrong. I went to great lengths to get the install done correctly. Hmmm, apparently I missed something. I have a long exhaust hose run and have a Vetus LP60 muffler installed that holds 2.77 gallons of wet exhaust, which I thought would take care this. Maybe not. I am ordering a LSL60 which holds 4.23 gallons of wet exhaust. I have a high vacuum loop installed on the water injection hose and a high loop in the exhaust hose itself. That is the way several Rasmus owners I have talked to have theirs set up. The only thing I can think of is that the duration of cranking the engine without a start caused water to accumulate in the muffler to the point of backing up in the engine, not having enough pressure to blow out the wet exhaust. Any thoughts out there would be appreciated. I am thinking that the insufficient fuel level caused the hard start, which caused the back flow of water into the engine, and also saved my engine from destruction when it wouldn't start before I checked the oil level and found the water in the engine. Whew!! Question: What size exhaust muffler are you Rasmus owners installing in your boat? Do you put a loop in the exhaust hose? Also, I want to know how you experienced owners handle hard engine starting situations, specifically, after cranking the engine over an unusually long period of time without a successful start, do you empty out the wet exhaust muffler at some point to keep water from backing up in the engine? Any ideas are appreciated.

Thanks

Pat

Thanks

Pat

Friday, October 12, 2012

Beta 38 engine is up and running

Well I received my new custom engine mounts and they worked great. I have roughly aligned the engine and hooked up the exhaust and electrical. I also hooked up a facet pump (part number 40104) in front of the Racor fuel filter to help lift fuel out of the deep fuel tank. After running it a bit, I blew the 1 amp fuse to the facet pump. I continued to run without the fuel pump. The next day I tried to start the engine (Beta 38) and it would not start. I then realized the facet fuel pump is really needed on this boat/engine combination. I replaced the 1 amp fuse to the pump with a 5 amp fuse and ran the fuel pump a bit before trying to start the engine. No good. I had to re bleed the fuel lines before the engine would start. This was a good lesson to what is needed to get this combination to work well. That facet pump is much needed.

Monday, October 1, 2012

New engine in 'Michaela, Rasmus # 330

I just tore out the old Volvo MD2003 from my Rasmus # 330, Michaela. Here's the new engine - a Volvo/Perkins D1-30. It's a vast improvement! The new prop is a Campbell Sailor 3-blade.

Saturday, September 29, 2012

Blog I Found Interesting

Here's a link to a blog about a guy named Nathan that cruised from Ft. Smith Arkansas down the Ar and Miss Rivers to the Gulf and on to the Florida Keys and the Bahamas in a very small boat . Check it out.

http://sailingmatilda.blogspot.com/2009/12/toad-suck-lock-and-waltzing-matilda.html

http://sailingmatilda.blogspot.com/2009/12/toad-suck-lock-and-waltzing-matilda.html

Friday, September 28, 2012

Bingo!

I was missing a few parts from the Hella Marine Anchor light on my Rasmus and searched the internet with little hope of finding them. I found the exact light from Wolfs Marine right here in the USA. I went ahead and bought the entire unit for the low price of $49.00(on sale from $115). The packaging was old and yellowed and a bit tattered (which Wolfs apologized for) but it contained a beautiful and well made light from Hella Marine. I bet it was the only one in the United States for sale. Miracles do happen.

Wednesday, September 12, 2012

An Update from Pat

I am now waiting for the second set of custom engine feet to arrive before I can get the engine in its spot. In the meantime I am finishing up some interior woodwork which included making four drawers and 2 doors for the galley. I used cherry for this job. I am also doing some finalizing on solar panel installation and I put in a lightning ground plate where the Dynaplate was located and moved the Dynaplate. After reading a lot on grounding systems, I am getting a better feel about this fairly confusing and contradictory subject. It looks like the lightning ground and DC ground are kept separate, and that's what I am doing. It also looks as though the SSB radio ground is kept separate from the DC ground, but I've read that you can accomplish this via electronic circuitry. My engine should be installed in a few weeks and then I will finish the mast rebuild. That will get me very close to getting the boat in the water. I am planning a 4 month cruise starting in February 2013. I will start from Little Rock, Arkansas and cruise down the Arkansas and Mississippi Rivers to the gulf and head to Key West and then the Bahamas. I expect my brother to join me there and we will cruise the Bahamas for a month together before I drop him off and head......well, who knows. I hadn't decided yet. I will start another blog and document my travels as they happen.

Cheers

Pat

Cheers

Pat

Wednesday, September 5, 2012

Communication Problem with Beta Marine

Well, I have spent over $800 on the wrong size custom engine mounts from Beta Marine just because Beta didn't tell me that I had to subtract for the flexible mounts to be used in the installation. The HR Rasmus 35 does not have long flat engine beds, so it is impossible to use Beta Marine's measurement worksheet that they provide in ordering custom engine mounts. But I had my original engine, the Volvo MD21A, and asked if I could take measurements off of it. Beta said no problem. I had the engine head off so I had a nice flat surface to extend a straight edge from it to get the measurements for the engine mounts and transmission coupling. In all the conversations I had with Beta never was I told that the flexible engine mounts used in the installation needed to be taken into the measurements. So when I received my final drawing from Beta to sign off on, I focused my attention on the dimension figures, which all were correct, but failed to notice that the dimension lines for the height of the engine mounts terminated at the base of the flexible mounts, not the engine mounts(feet), a difference of about a 1/4 inch on the drawing. This mistake led to an engine that sets 2 1/2 inches too low. I argued my point with Beta and they gave me a discount on new custom engine feet(not enough in my opinion). So now I am ordering new custom feet from Beta Marine and have a few weeks before they are delivered. So my hassle free engine installation has turned into a hassle. I will move on to some interior woodwork projects as I wait.

Cheers

Pat

Cheers

Pat

Thursday, August 23, 2012

Had a great week on the boat early August - didn't go that far just cruised round the Clyde as there wasn't much wind and we had commitments to sail with friends etc.. Took these Photos which I thinks shows off my local cruising waters at their best. The first is looking up the Kyles of Bute from off Rothesay and the second looks across two islands, Great Cumbrae and Bute towards a third Arran

I'd like to say its always like this round here but alas its not!

Euan

Cabatach

I'd like to say its always like this round here but alas its not!

Euan

Cabatach

Sunday, August 12, 2012

Making up 1x19 ss standing rigging

I made up my standing rigging using 1/4 inch diameter 316 stainless steel wire. Below is a pictorial/description of how I did it.

|

| The swage end of the rigging slipped onto a 1/2 inch dowel pegged to the shop floor and numbered |

|

| I used a block of wood with a 1/4 inch diameter hole drilled thru to hold the rigging wire. |

|

| Cutting the wire with jig saw or hack saw. |

|

| Sanding off the rough edges with rotary sander. |

|

| Slipping on the head of the Hi Mod fitting |

|

| Unwind, don't bend, the outer wires one at a time. |

|

| Place the inner cone on the inner wire core. |

|

| Slip the grooved washer onto the inner core of the wire. |

|

| This is how it should look just before screwing the eye onto the head. |

|

| Tighten the eye on the head by rotating either the eye or the head so that the one chosen will be in the direction that will not unwind the wires. |

Friday, August 3, 2012

Just Added a Link to a Great Sailing Web Page

I was searching the web today and found a very nice web site with tons of great information in it about cruising. It is Geoff Schultz Bluejacket Sailing Site. Check it out. It is certainly worth looking over if your planning on cruising around North America.

Cheers

Pat

Cheers

Pat

Monday, July 23, 2012

Beta 38 Installed in Rasmus

I hoisted the engine up and into the Rasmus today with the help from my two daughters. It took all of 30 minutes. It went in without a hitch. But (there is always a but isn't there) the engine is designed to sit at an angle so the four flexible engine mount bolts are also tilted on the same angle. From what I have read that is not a good thing. I have contacted Stan from Beta Marine to ask him what the next step is. I am hoping he says, "Oh don't worry about that Pat, it won't cause any problems at all." Anyway I have a couple of pics below.

I had to take the exhaust elbow off for the engine to fit in the hatch. That was not a problem. Other than that it was a smooth operation. Cheers.

Sunday, July 15, 2012

Electronics, Engine, and Self Steer Gear

In the last few weeks I have been busy installing electronics, getting the engine room ready for the Beta Marine 38, and finishing the CapeHorn installation. Pics below:

|

| I replaced the fuel lift tubes. The old ones were looking brittle. |

|

| I finished rigging the cape horn wind vane to the tiller handle. |

Wednesday, July 11, 2012

Beta Marine Engine for Rasmus

I ordered a Beta Marine 38 hp engine for this Rasmus. It will be arriving tomorrow. I purchased custom engine mounts that should make installation easier, hopefully. I will post comments and pictures as the work progresses.

Sunday, June 24, 2012

Vetus HTP30R steering pump

For anyone dealing with steering issues, I recently replaced my Vetus steering pump. The new pump is the Vetus HTP3008R. My old steering cylinder seems good so I didn't replace it at this point. I had to bleed the lines and cylinder several times. The first time, any pressure on the rudder during a port tack would return to center. Mounting the emergency tiller made it easy to watch the movement. I found it was necessary to fill and bleed the lines with the cylinder in various positions before all the air was out. I couldn't be happier with the new pump. The install was a quick easy swap.

Best wishes, JK

Best wishes, JK

Saturday, June 9, 2012

Article from Anthony Fitch sailing Windsong

Here is a PDF document that Anthony Fitch sent me about a journey on his HR Rasmus "Windsong". Enjoy.

boat with the use of the bowthruster – very useful as we have found on a

long keel boat. We booked an

engine service and finally tracked down a German vet to

get

Micky’s passport stamped for tick and worming treatment ready for border control at Calais.

had brought the car again – so much gear to bring - and left it at the marina, not sure how far we would get. For its retrieval we would have to do

battle with the German public transport, but that should be the

easy bit.

had brought the car again – so much gear to bring - and left it at the marina, not sure how far we would get. For its retrieval we would have to do

battle with the German public transport, but that should be the

easy bit.

but as we drove back to Bensersiel the wind

was

blowing hard and not doing much for my nerves. We left the car by the ferry terminal and caught the ferry back to Langeoog, together with our friends Nik

and

Heather who had come out for a week. It was so windy we lost a whole day, with some blustery walks on Langeoog but the next day we took the inner channel along past Baltrum to

Norderney. It was

still wet and quite rough but they raised the Union Jack as we came in and we were made very welcome.

but as we drove back to Bensersiel the wind

was

blowing hard and not doing much for my nerves. We left the car by the ferry terminal and caught the ferry back to Langeoog, together with our friends Nik

and

Heather who had come out for a week. It was so windy we lost a whole day, with some blustery walks on Langeoog but the next day we took the inner channel along past Baltrum to

Norderney. It was

still wet and quite rough but they raised the Union Jack as we came in and we were made very welcome.

Nice day for sealing! Off Baltrum

1st August Zoutkamp to Leeuwarden

13th /14th September Dover to Chichester Harbour

Buying in Germany

Journey from the Baltic

The decision to buy a Hallberg Rassy started by pure accident after

we

rafted up

to a 34 and thought

what

a lovely boat it was. We wanted something bigger (as you do!) than our Mirage 28, with good sea keeping and two cabins to

take occasional guests in a

bit

more comfort. Some research revealed

that a HR 34 or 352 had rather too deep a

draught for our (then) conservancy Nutbourne Channel mooring in Chichester Harbour but the older model long keel Rasmus 35 was a mere 1.3 m and a

few

were for sale locally. We liked the boat

with its deep centre cockpit but the ones we saw were

suffering from some combination of osmosis, horrible engine, worn teak deck or scruffy interior. However, an internet search brought up two for sale

near Lubeck in the Baltic that looked in excellent

condition so off we went for a weekend of boat tourism. Lubeck makes for an interesting City visit and the Rasmus 35 ketch ‘Questus’ was the best one we had seen with no

osmosis, nice teak deck and a

nearly new engine. Then it all got serious with an offer

made and accepted, a

satisfactory survey and deposit paid.

This

all happened back in October 2007 when the Pound was steady against the Euro and the boat

was

a good buy. We transferred the money to the German Broker in the nick of time as the first hints of the Pound’s problems occurred. Writing now in 2011 the Pound/Euro exchange rate

makes buying abroad a less attractive option. Indeed, many UK boats are no doubt heading in the opposite direction, as good

buys for anyone with a wad of Euros in their back pocket.

What

we should have done next was drop the masts, hire a low-loader and wait

for the boat’s arrival at

Thorney Island. But

we

didn’t of course and we were committed to

our great adventure in the summer

of

2008.

Getting Ready

May 2008 was glorious weather in the Baltic. We drove to

the Ancora Marina, Neustadt in Holstein, with our well-travelled

Collie Micky, to meet up with the boat’s former owner for a proper handover.

This in itself took some organizing, given that

he

and his wife spend the winters in Spain. Jochen proudly showed us the sprung slats under the 6 inch cushions in the forecabin and the Volvo Penta D2

55 he had bought to replace the original MD21. Unfortunately he hadn’t looked after the fuel tank so well, but

more of that later. Jochen gave us all his Baltic and North Sea charts and advised that

we

take the ‘inside’ route to Holland, masts down using the canals. We politely

listened, ignored his advice

and now know it wasn’t such a

bad

idea! We wanted to set off as

soon as possible but

we

made use of

the incredibly efficient German boatyard services and splashed out on some new mast winches and

halyards to replace the original wire ones. Then there was a beautifully made new sprayhood. I

antifouled the boat, we applied our new SSR number and renamed it ‘Windsong’ with due

ceremony. It was launched and we motored around to our temporary berth with Jochen on

hand to help park the

Neustadt

16

June, Neustadt to Orth on the Fehmarn Island

We got back to Neustadt in June to finally set off,

minus dog but plus a friend Mike from work. We

had brought the car again – so much gear to bring - and left it at the marina, not sure how far we would get. For its retrieval we would have to do

battle with the German public transport, but that should be the

easy bit.

had brought the car again – so much gear to bring - and left it at the marina, not sure how far we would get. For its retrieval we would have to do

battle with the German public transport, but that should be the

easy bit.

Fehmarnsund bridge

We had a final delay when the engine started but

was failing to pump cooling water. The mechanic fitted another impeller and turned the cover plate back to

front to get a better seal. The weather on our maiden voyage was mixed, everything from sun to

hail but the wind

was fair – we got main, mizzen and jib

raised, engine switched off and enjoyed the Baltic. The navigation was straightforward –

around the coast and under the impressive Fehmarnsund bridge to

Fehmarn island. On arrival the harbour at Orth presented another challenge – our first encounter with a ‘Baltic mooring’ – in between (and hook) two posts and ease

up to the jetty for the brave crew to

leap ashore. We arrived with the light fading at a

quarter to

ten and the only place open to

eat was a the Taverne Syrtaki – a Greek restaurant – weird!

17

June, Orth to Laboe

In the morning we met and paid the friendly harbourmaster (they were all friendly, wherever we went –

it

must be a great job!). The weather was less favourable and we motored into the wind. We chose a

course close to

the

shore for interest but this turned out to be a mistake. Its funny how sometimes all the clues can be there but you fail to come to

the

obvious conclusion until its too late!

I mean, firstly we were alone - all the other

yachts were sailing along a

few

miles off the coast. Secondly there was

the

smoke rising up on the shoreline and finally there was the German warship that seemed to be

pointing directly at us.

And then the VHF Channel 16

came to life in German: ‘Yacht sailing under engine at position 54° 23′.6 N,

10° 47′.2 E

respond’. My O

level German was up to a translation and

yes, there were the same set of numbers on our GPS. In fact the German Navy was very polite and told

us

to head north to 54° 30′ to

exit the Todendorf Firing Danger Area before continuing with our journey. How had we missed the flashing yellow buoys that

guard the Danger Area I

am

not sure but

their meaning is only too clear

from a close inspection the chart Notes. After that excitement the trip to the Marina at Laboe was fairly uneventful. In

Laboe itself, we had excellent fish and chips at one of

the harbourside restaurants.

18

June, Laboe to Brunsbuttel

We departed from Laboe at 0800 for the sail to

Kiel-Holtenau where we locked into the Kiel Canal

(Nord Ostsee Kanal), paid the dues and set off in

glorious June sunshine and about 7 knots. Max speed in

the canal is 8 knots so we had the occasional ship creeping past us at 1 knot. The canal is now over

100 years old and the forested banks are very scenic. It was a long day though, given its length of about 55 miles and at about 6 p.m. we entered the small marina at the North Sea end in Brunsbuttel.

After a useful chat at the marina office we realized that

we

needed another early start to

catch the ebb tide out of the Elbe estuary to Cuxhaven.

Kiel

canal

19

June, Brunsbuttel to Cuxhaven

With the ebb tide (and our first taste of tidal waters now that we had left the Baltic) we departed at

06:15 at 9 knots for a very rapid trip to Cuxhaven (again into the wind and under engine). We berthed

at 0825, just in time before the wind got up

so

we had a blustery walk ashore. That evening we ate at a bar where the main concern was the European cup match between Germany and Portugal. We found ourselves supporting the Germans as each time they scored (and that

was

three times), all the customers

got a free beer.

Cheering on

the

Germans with free beer

20

June, Cuxhaven to off Spiekeroog

The

wind

was still blowing quite strongly the next morning but we set off anyway. More seriously as it

transpired, there was no diesel in the marina and we hadn’t been able to top up the diesel tank which

was now reading half full. We were now heading into Erskine Childers ‘Riddle of the Sands’ country

but not planning on any risky shortcuts. We had prepared a route with options to take us into some of the German Frisian islands, depending upon how far we got. We took the deep water channel around

Scharhorn and turned west, which was almost straight into the wind and slowly crept past

Wangerooge.

The engine, which had run thus far without missing a beat, was now distinctly coughing and

spluttering. I took a look at the fuel pre-filter and the glass bowl was filled

with a distinctly unhealthy

brown

crud. Switching over to the second filter

was to no

avail; the engine died and left

us

sailing close to the wind along Spiekeroog.

With

the light failing we arrived at the Spiekeroog channel fairway buoy. Mike was up for trying to sail in, Tineke was seasick and was desperate for it all to stop but I decided that the only safe option was to

stay out at sea and that

is what we did. The ketch rig came into its own now. With the mizzen sail plus about half the jib, the boat was nicely balanced and we (that is to say Mike and I, Tineke was

down below miserably clutching a

bucket) sailed up to the shipping lane, tacked around and back to the

10 m

contour, repeat, many times. Our chart for the night of 20

June looks like a demented spider has been drawing all over it as

we

tracked up and down, the tidal stream taking us back towards

Wangerooge and then returning us at dawn to exactly where we had started, off the Spiekeroog channel.

21

June, Towed into Spiekeroog

I am not sure what flavour of gale we survived that night, the boat not having a wind speed gauge but the carnage down below was impressive. Nothing remained on any shelf and the saloon looked like a

war zone. But I was sold on the boat; it had taken it all with aplomb. The

weak link was us, a

pretty inexperienced crew. Tineke had had enough by this stage and gave a PAN PAN on the VHF. The

SAR boat arrived about half an hour later

and towed us into Spiekeroog. It was a small consolation to

be

told that we done exactly the right thing; we would almost certainly have lost the boat if we had

tried to enter the harbour in those conditions.

After a few hours much-needed sleep the contrast was astonishing; the sun was shining, the wind had dropped completely and we were moored in a beautiful harbour. Tineke, now much recovered, went

off into the town in search of a mechanic. Mike, his holiday over, got the ferry to the mainland and

made his way to Amsterdam for a flight home.

Frisian Island Route taken

Tineke came back highly amused for we had been towed into an island with no

cars, no mechanics and no

diesel. Lots of nice restaurants, tea rooms and holiday homes, bicycles for hire and a

few horse

drawn carts, but no

diesel!

I borrowed a

very impressive tool kit from our friendly motorboat neighbours but quickly realized

that this was beyond me. Everything was clogged with the treacle-like glue of diesel bug. I had read about it and now I

knew what it looked like. Luckily we had noticed an internet café and we set off for lunch

with the laptop. An internet search brought up just what we needed – Horst Janßen at Yacht Motoren

Technik, a mobile marine mechanic who spoke English – perfect!

Meanwhile our ‘replacement crew’ Dan and Becky arrived after a very interesting trip from

Amsterdam. They were dinghy sailors but

keen to try some cruiser sailing. All

we

could offer them for the time-being was sight-seeing on Spiekeroog, but they accepted this rather different holiday

experience and we enjoyed some coastal walks plus some of the excellent restaurants on this very

unspoilt island.

Becky at Spiekeroog

Horst Janßen arrived the next day loaded with jerry cans of diesel on his small motorboat. He set to

work in the engine bay and cleaned out both the pre-filters but there was a further problem. The pipe from the diesel tank was undone and found to be clogged with yet more of the treacle-like crud. He filled up

the tank, bled the engine and it started instantly. He then presented an eye-watering but not unreasonable bill, given his trip from Dornum to get to us and I raided the island’s one and only cashpoint machine for the necessary wad of Euros. With a

final warning that we must get the tank properly cleaned as soon as possible, he departed in his motorboat.

The 25th of June was a beautiful sunny day and we should have got up really early to depart on a rising

tide

but we didn’t. Perhaps we had slipped into holiday mode and forgotten that this was actually some kind of endurance test. Anyway, the tide was starting to fall as we motored down the channel. The ferry

from the mainland came around the corner, I

got out of the way and we went aground on a very poorly marked bit of channel (my excuse). The only good news was that the boat leaned over onto the

edge of the ill-marked sandbank and some people we met later thought we had done it deliberately! Well, we did have a nice picnic on the sandbank in the sun, admiring the boat’s bottom that

I hadn’t really wanted to

see. The tide duly came back in, the boat re-floated and we went back into the harbour for an unscheduled extra night.

Unscheduled picnic at Spiekeroog

The

harbourmaster didn’t charge us for that extra night, maybe he felt a bit embarrassed about the

poorly marked channel. The visit

was

very useful though, as we got some excellent advice from another sailor that our 1.3 m draught was easily capable of taking the inside channel between the

islands and the mainland, provided of course, that

we

got the tides right.

26th June Spiekeroog to Langeoog

No

messing this time, we all got up at the crack of dawn and crept away on the rising tide. We then

stuck close to

the

withies, proper riddle of the sands sailing, fearing that we would go

aground again.

In

fact, if only we could have felt a

bit

less stressed, it was a lovely and straightforward trip to Langeoog. It just didn’t seem it at the time.

The

harbourmaster was a bit alarmed when we asked to

leave the boat for a

fortnight (work getting in the way) but

we

promised to

bring back some books for his English speaking girlfriend (who was so grateful she did all our washing for free). We then had to

get a ferry to the mainland, a bus and two

trains and a

taxi back to the car and the long drive home, after

which a fortnight at work actually

seemed quite restful!

15th July, Langeoog

Following the withies

We just

were not getting any luck with the weather. The fortnight in England had been quite pleasant

but as we drove back to Bensersiel the wind

was

blowing hard and not doing much for my nerves. We left the car by the ferry terminal and caught the ferry back to Langeoog, together with our friends Nik

and

Heather who had come out for a week. It was so windy we lost a whole day, with some blustery walks on Langeoog but the next day we took the inner channel along past Baltrum to

Norderney. It was

still wet and quite rough but they raised the Union Jack as we came in and we were made very welcome.

but as we drove back to Bensersiel the wind

was

blowing hard and not doing much for my nerves. We left the car by the ferry terminal and caught the ferry back to Langeoog, together with our friends Nik

and

Heather who had come out for a week. It was so windy we lost a whole day, with some blustery walks on Langeoog but the next day we took the inner channel along past Baltrum to

Norderney. It was

still wet and quite rough but they raised the Union Jack as we came in and we were made very welcome.Nice day for sealing! Off Baltrum

Anthony and Tineke Navigating the Frisian isles

18

July Norderney

to Delfzeil

The harbourmistress at Norderney warned us that even worse weather was coming and we had better

leave the next

morning. We had decided to

escape the horrors of the North Sea for the wholly new challenge of the Dutch canal system. Technically, this was our most challenging day as

we had to cross two drying channels on a single tide. We departed at dawn, well before the 12:00 high tide. We had a taste of how rough it was ‘outside’ in the North Sea as we crossed the inlet between Norderney

and Juist. It was all eye-ball pilotage, no

GPS

required, trying to

spot the channel markers in the rough

sea

as we found our way into the ‘Memmert Wattfahrwasser’, the narrow drying channel marked by withies that took us along the coast of Juist. There was enough water to

get

us over the first drying section at 10:00 and the channel then widened and deepened all the way to

Memmert where we turned

south into the Eems estuary towards Delfzeil. We arrived at the second drying section at exactly the

top of the tide and could then start to relax as we reached the main shipping lane to

Delfzeil. The

weather was truly awful but Tineke did have the joyful moment of hauling down the German courtesy

flag and replacing it with the Dutch one!

19

July Delfzeil to Zoutcamp

We met a

lovely Dutch family in Delfzeil who were heading the same way as us and said that we could

follow them to

Zoutkamp (where there was a favourite marina of theirs). It felt wonderful to

have no

navigation worries for a change and simply follow the boat in front, chatting away on the VHF. Even

so it was pretty hard work getting through the locks and the many lifting bridges of Groningen.

En route to

Groningen

Groningen – one of many bridges

The

Jachthaven Hunzegat at Zoutkamp was indeed a good suggestion. It was family-run, with the wife doing the marina bookings and the husband plus son-in-law carrying out

maintenance work. We left the

boat there and they more or less adopted the boat, agreeing to

empty and clean out the diesel tank

and

more horribly, sort out a

blocked holding tank. Then yet another trip back with the car but at least the distances were getting smaller.

Fixing the VHF antenna at Jachthaven Hunzegat, Zoutkamp

1st August Zoutkamp to Leeuwarden

We were seriously running out of leave by this stage but came back for a

‘long weekend’ to

see what

progress we could

make. We had a

pleasant canal trip to Leeuwarden – a

lovely town but the canal

banks were very crowded at the height of the holiday season and we had a job finding anywhere to moor up. The next day we continued on to Harlingen (a delightful harbour town) and found a marina

where we could leave the boat for 10 days.

Leeuwarden

Another long weekend and travelling by public transport from now on,

flying to Amsterdam and using

the train. We went through the sea lock and followed the channel to Den Helder, where we moored up along with the Dutch Navy. We phoned ahead to

IJmuiden but were told that we couldn’t leave the boat there as they had very limited space. So we had to leave the boat at Den Helder and lost the opportunity to get any further.

5th September Den Helder to Vlissingen

Our Day Skipper instructor Trevor Clifton agreed to give us a hand for the final leg. Trevor has sailed

his Twister 28 single-handed across the Atlantic and around Cape Horn so our trip was pretty

straightforward to him. His arrival was a boost to

our confidence but the weather remained as awful as

ever. We departed from Den Helder at dawn for the long trip down the Dutch coast. There was a gale warning that didn’t help but we pressed on, getting up

a good speed with reefed main. Trevor suggested that we should have a third reef when we replaced it (surely not, plenty of life left in that) and

not so long later

‘bang’, the sail ripped in a

gust but

was still

usable on the second reef. We got across the incredibly busy Rotterdam shipping lane and the final leg into Vlissingen seemed to take

forever, with me helming in the dark and Trevor navigating but finally at dawn we got to

the

lock gate and into the harbour marina.

7th September Vlissingen to Dover

Departing Den Helder

We spent the day recovering and it wasn’t until 0400 that the weather relented and we departed

Vlissingen. It was a point to note about professional skippers; they go when the weather permits, day or

night. The weather slowly improved as

we

went down the Belgian coast and then on towards Calais

and

across the channel. The sea was now flat as a mill pond, so

much so

that the channel swimmers

club were in action. We saw their very slow-moving motorboat guarding its little flock of swimmers

doing the crawl. We crossed in the dark and into Dover harbour, registered the boat and awaited the

taxi we had booked to

get

us home.

Trevor

13th /14th September Dover to Chichester Harbour

At last the logistics were getting easier. We hired a car and took Mike plus girlfriend Sue to Dover for

the trip to Chichester. We filled up with diesel at Dover with what I guess was the first red diesel ever

to go in the tank. The sun shone, the wind

was

light and the sea sparkled – better late than never and we had a delightful trip along to Brighton marina.

Nice weather at last en route to

Brighton

The

next morning we left just

before dawn, having done the sums to arrive in Chichester harbour on the top of the tide. It was tricky looking out for the lobster pots that seemed to

be

sprinkled with gay abandon off Brighton Marina but after that we had another nice day’s sail and celebrated with a bottle

of

champagne when we finally tied up

to our swinging mooring in Nutbourne channel.

Tineke and Mike celebrating arrival at mooring in

Chichester Harbour

Anthony Fitch, Windsong February 2011

Subscribe to:

Posts (Atom)